Frames for bee hives: choice of sizes, making yourself

Beekeeping is a rather painstaking business, requiring a lot of time, effort and knowledge. The habitats of honey bees are specially designed hives, the basis of which is the framework.

Types of bee frames

Depending on the size and configuration of the bee hive, there are standard and non-standard frames that are suitable specifically for each hive.

Did you know? In order to produce 500 g of honey, one bee must fly 10 million times from a flower to its home.

Covering

They are located at the two edges of the nest and should be dark. Their main function is to store heat in the bee’s nest and to separate it from the empty space in the hive. They are filled with honey and bee bread, cover brood frames, and honey honeycombs are used in front of the cold weather.

Feeders

For proper care of the bee family, special feeders are needed, the essence of which is feeding insects.

They have to:

- provide access to feed in any weather;

- easy to clean and wash;

- prevent bees from drowning in syrup;

- exclude contact with insects during feed distribution;

- protect from bees from other hives;

- enable the beekeeper to monitor the consumption of food.

Incubators, nurseries

For mass breeding of queen bees, incubators are widely used. They look like standard frames, which are placed in the middle of the nest. For normal maturation of the uterus, it is necessary to maintain a temperature of +34 ... + 36 ° C and a relative humidity of 60%.

We advise you to read how to make polystyrene beehives with your own hands.

Nurseries are an ordinary nesting frame, to which movable thin slats are attached on the sides. Their goal is to place the uterine cells with the mother liquors.

Saver

The curtain frames are used to warm the bee house and are made in the form of a solid wooden plate made to the size of the hive. A heater is inserted between the side wall and the head frame.

Construction

To obtain wax from bees, reduce the number of drones and fight against bee disease, prepare building frames having standard sizes and place them in the center of the nest. A wire is pulled in the middle of the side planks, a layer of wax is distributed on top of a width of 3 cm.

Video: Building frame in a nest of a bee family

Sectional

Used for the production of honeycomb. They are made in the form of standard half-frames.

Important! It is necessary to inspect the hives at a temperature not lower than + 15 ° C, because if it is lower than + 13 ° C , then the bees may have muscle spasm and they will not be able to fly.

Wood or plastic - which is better

To replace the wooden frames came shop, made of plastic. Each species has its advantages and disadvantages. They are as follows.

- Pluses of wooden:

- They are inexpensive and can be made independently;

- the tree does not contain any chemical additives;

- well retain heat and provide ventilation.

- Minuses:

- under the influence of various temperature differences lose their shape;

- damaged by pests;

- weigh more than plastic.

- The positive qualities of plastic frames include:

- strong enough, convenient for transportation, do not damage the wax;

- shelf life is much longer than that of wood;

- do not absorb honey;

- lighter in weight;

- used in any honey extractor.

- The disadvantages include:

- if damaged, they cannot be repaired;

- bees process worse wax;

- best used with excellent wax formation.

Size selection

The choice of frame size depends on the size of the hive structure. They should be well fixed, conveniently extended.

The main requirements for the placement of the frames are the following distance parameters:

- between the centers of adjacent honeycomb frames there should be a gap of 37–40 mm;

- from the upper and lower bars to the hive body - 8–10 mm;

- from the last lower frame to the bottom of the hive - 20-30 mm;

- top beam - 25 mm;

- from the walls of the hive to the sides of the frames - 6 mm.

Read also how to make a rue hive with your own hands.

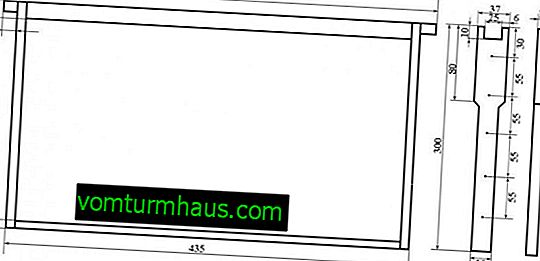

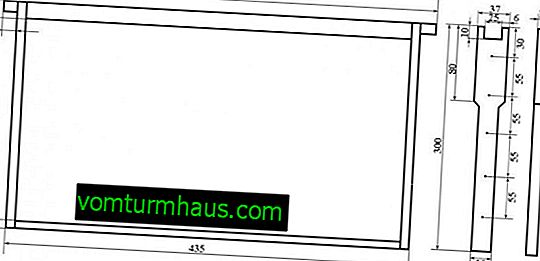

Standard parameters for 1 frame:

- width - 2.5 cm;

- the upper bar is 1.8 cm thick, the lower is 1.5–2.5 cm;

- height - 14.5 cm.

DIY homemade frame collection

Frames can be bought ready-made in a special store, you can still purchase the necessary blanks and just fold them, but some beekeepers prefer to make them yourself at home, sticking to the drawings.

Video: Frames in a do-it-yourself hive

The principle of construction

The standard frame consists of an upper, lower and two side strips of the same length. An exception is the upper bar, which should be a little longer and protrude beyond the size of the entire structure. If the choice is limited to wooden materials, then they need to be sanded with sandpaper and made smooth. When using coniferous wood, plus this, it is also necessary to cover it with wax or drying oil. The joints are lubricated with glue, and the strips are twisted using steel screws that grasp the structure well.

Important! After applying the glue, all further actions must be done quickly and accurately, as the glue dries quickly.

Frame layout options

The amount of honey collected in the future will depend on how correctly and efficiently the beekeeper arranges frames in his hives. Frames can be placed longitudinally or transversely with respect to the hole for the departure of bees from their home. The longitudinal position is recommended to be used by specialists who own a large apiary, since this option helps to quickly examine the frame. It is better for inexperienced beekeepers to use the transverse arrangement, thanks to which each frame is inspected separately.

Wire frame

When choosing a wire for frames, it is necessary to take into account the requirements for its properties. It should not stretch over time, not rust, be comfortable when fixing it on the frame, so it is recommended to use steel wires - black and stainless. Black is cheaper, softer than stainless, but it can rust from exposure to frames. Stainless steel, or high-alloy wire, is used longer, costs more and stretches harder on the frame because of its rigidity.

Wire pulling technology

After the frames are ready, you can begin the process of pulling the wire in order to later fix the transition wall from the wax on it. For this purpose, it is necessary to have a coil with a wire, a screwdriver or drill, a drill jig, a hammer, nails, pliers and pincers.

The technology of pulling the wire consists of the following steps:

- Using a conductor, make holes in the antagonistic bars depending on the location of the strings.

- Nail nails on which the wire will be pulled.

- Pull the wire through the holes with a snake.

- Wrap one end of the wire around a suitable nail.

- Pull the wire with pliers and wind the other end onto the second nail.

- Finger along the strings to make a musical sound, in case of its absence - repeat the tension.

Did you know? Scientists from the United States specifically teach bees to find explosives.

Useful Tips

Experts recommend making beehives from coniferous species of wood; pine is best suited, which is easily processed, does not deteriorate for a long time, and is rich in resin. In the production of frames, beekeepers most often use linden or a Christmas tree, because they are easy to use and do not crack.

Today there is a wide selection of frames that you can choose and buy depending on the material of manufacture, cost, and also on the shape and size of bee houses. But you can also make them yourself, following the instructions, because they are a very important element of the entire hive.